Bronco Driver: How did you first get involved with Broncos?

Nick: Back when I was in high school, there where a couple of guys who had them. I noticed them one day and really liked the way they looked, something about the Bronco drew me in. I decided that day that I wanted to drive a Bronco. I worked all summer as a construction laborer and saved enough money to buy one. To tell the truth, I actually ended up buying it off of one of my friends. That was in 1981, I still have it today. Although I do take it out for a spin once in a while, for the most part it lives comfortably retired in my shop.

BD: Tell us your background... Did you grow up in Charlotte? Are you married? Kids?

N: I actually grew up in southern California, in the LA coastal area. I tried college for a couple of years where I was working on a construction technology degree. While in school, I went to the Baja 1000 and got hooked. I decided I was ready to get into the work force in 86. As I was working as a carpenter, I was also helping out a local off road race team. By that fall I realized racing is what I wanted to do and was working full time in it by the onset of winter. Off road racing was very good to me. I learned quite a bit, had the opportunity to work with some great people, all the while getting the opportunity to travel and see places I wouldn't have otherwise.

In 92 I decided it was time for a change. I had heard great things about the opportunities NASCAR had to offer. So I moved out to NC at the end of that year and have never really looked back. Racing has been a great career for me and I do feel as though I have been blessed. I've been able to do something I enjoy and have made a comfortable living doing so. Its hard to believe its been 20 years this fall since I got my start in this business.

I am married to a very supporting loving & wife, Meredith. We have a sweet 3 year old daughter named Karis. Oh, we can’t forget our fur child, "Chico", he's our collie.

BD: How many Broncos do you currently have?

N: I currently have 6: 2 are drivers, the rest are parts trucks. I pick up parts trucks from time to time, its good to have a constant supply of organ donors you can say.

BD: What is the story with getting involved with Ford and Robert Yates/Roush engine building?

N: Well, I started working for Robert in 2002. Towards the end of that year I was ready to shift away from the race team side of things. As it turned out the timing was perfect as the engine shop was just preparing to move into a brand new state of art facility he had been working on for 2 years. Anytime a race team moves, there are a number of things that need to be built. With 70 K sq ft of new shop, there was ample for everyone to do. I spent a couple of months just building facility things, from dyno parts, overhead cranes to clothes racks, it all has to get done. The "manufacturing division" at that time consisted of myself and one other guy.

Once the race season began looming we redirected our efforts on building all the things our dept was traditionally responsible for: those are exhaust headers, oil pans & a number of other internal pieces. In the fall of 2003, the company grew substantially with the merger with fellow Ford team owner Jack Roush.

The merger created a Ford super power within the NASCAR world. With the combination of technologies, resources and staff, it has become a tough package to beat. Ford Racing and Ford Motor Company are very involved in our programs. Our company has grown to 2 facilities and supports 27 teams between the 3 NASCAR major series. You could say "we build the power behind the Blue Oval in NASCAR".

BD: Did you know Edsel Ford had an Early Bronco restored not too long ago?

N: He was by our facility a while back. I didn't get the opportunity to ask him about it unfortunately. I thought that it would have been fun to talk about for a few minutes.

BD: What was the first product Nick’s Trix manufactured for the Bronco?

N: Well, actually back in the mid 80s I had a front double shock kit. I sold a few, but nothing on the scale of today. The first publicly marketed part was our billet windshield knob. I market them under the name "Retro Knobs".

BD: What year did you first produce for public marketing?

N: The Retro Knobs were introduced in the spring of ‘03.

BD: What are all the products Nick’s Trix manufactures now?

N: Besides the knobs, we do the stainless script logo keychain, the scuff guard dash protector, colored billet body lifts, lockable tailgate latch and have a couple new things, those being the mailbox topper and an billet column bezel, oh yeah, we got t-shirts made up this year too.

BD: What was the impetus behind some of your innovative products?

N: With the knobs, I always liked the way the original factory ones looked. The thing of it was is that it was hard to find any that where in good shape. I was aware of how much people where willing to pay for a crummy looking, rusty old set on e-bay and felt that if could make a modern version of the part I could probably sell a few. I figured the worse I could do was to break even, but at least I’d have a couple for my own trucks.

As it turns out they were a pretty good success and the foundation of what has become Nick’s Trix. The key chain was our next offering. My goal was to offer something that a child could afford with his or her allowance money. I wanted a gift item that the recipient could keep with them always. Hats and t-shirts weren’t going to cut it. That’s when I came up with the key chain. It’s a nice high quality item that is built to last and priced right

The new Topper came about as I thought a new fun item was due for the true Bronco enthusiast. It provides a means to show your passion to hose around you and the word. Mounted on the mailbox, it can also help guide your mailman to where to put ones new issue of Bronco Driver Mag! Seriously though, it's just a neat way to show your Bronco spirit. It's designed so it can be mounted on about any place your imagination leads you to. The other products have come about either as a need that I’ve noticed or as a design request.

BD: Any cool technology that makes Nick’s Trix products special?

N: I am fortunate to work with some great outside vendors in my day job and am exposed to some unbelievable in house machinery and technology. Our guys put out some unbelievable parts. This gets me thinking about things for the Bronco. Sometimes they just don't pan out because they end up being too costly for the market, but other times they lead to something. Sometimes it just takes a small idea to get the thought process going.

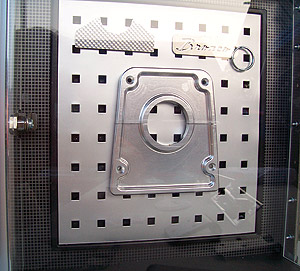

I try to make my parts so they are not only attractive, functional, durable but also affordable. My parts are CNC machined or laser cut. I use outside vendors to do this for me. I design it, they produce it, I assemble it and so on.

BD: Explain the manufacturing process?

N: CNC stands for Computerized Numerical Control. This means a computer program is written with special software to dictate the complete movements and tool changes that are required to machine that part or process. This way a part can be designed on a computer, a program written, material loaded into a machine and within minutes or hours, depending on the complexity of it, a part can be made.

BD: You offer many of your products I different colors, how do you get the color in the metals?

N: I anodize my billet aluminum parts. This is an electro chemical process that inhibits naturally occurring oxidation. The anodizing process colors the material by basically impregnating a dye into the pore structure and creating a colored film. This protects it from future oxidation. When done properly the part looks great for years.

BD: Any secrets into some new products we may see in the future?

N: Funny you ask that, I figured you would. I always have a number of things working, some further along than others. Right now I am at a good point in the year with what I have currently available. Before I bring additional parts into the product line, I try to have everything working smoothly with the job shops I use. Don't get me wrong, I have some great people making things for me, I just want to make sure they are able to keep up with the demand. Sometimes I’ll get ideas to improve a part and want to incorporate it in the next batch and so on. Right now I am really focusing on a current project I have in my shop. To tell the truth, its actually my own restoration / rebuild. You know how it is, your own things are the last one to get the attention. Well, after 4 years of being bumped, its bubble has finally come up. You can say I’m “pimping my own ride.” I have some really neat ideas planned for it resurrection. Currently its in the disassembly process, from there it will get sent out for a nice bath at the chemical stripper. It will come back completely bare. From there I’ll do any body repair required and my ace body man, Norm Lowe, will work his magic on it. He is the one that handled the refinish process on the truck I recently completed for Dr. Bubba McQueen.

BD: Where can Nick’s Trix products be purchased? Do you have your own web site/ordering or do you have to order through a distributor?

N: Our products can be purchased at the majority of the larger vendors. Jeff's Bronco Graveyard, James Duff Enterprises, Wild Horses, Tom's and now BC Broncos all carry products from Nick’s Trix. They each carry their own choices of the product line.

Occasionally I will introduce an IPO (Initial Public Offering) in mass buy format. It has been a great way to get a lot of people talking about our products. However, in all honesty, right now I'd rather be a supplier to the vendors than deal with the individual sales. Some of my parts are great lead in items for them or are good counter sale impulse items. with all I have on my plate, its just a better situation for everyone involved. Of course, I do have a web site, www.NicksTrix.com, where you can find pictures, information, and suppliers for everything.

BD: You have recently begun building custom Broncos for customers? Do you have others in the works? Are you actively seeking customized projects?

N: Yes, I do take on customer work. Right now, as I said, I have my own project happening and a couple of others that are patiently waiting their turn. I really haven't gone out looking for work. It somehow finds it's way here. That's a good sign. I'll take on a few quick side jobs that I can knock out in a day or weekend. Sometimes that gives me a break and allows me to clear my mind. With a day job that can be very demanding at certain times of the year, it can be a real challenge to try and juggle everything at once. Between family, job and business it can get overwhelming.

BD: What are the plans for Nick’s Trix in the future?

N: I’d like to do a couple of “spec” trucks, complete restorations with my own personal touches, call them modern amenities. I think people want more luxury in what I call a “street cruiser” version of a Bronco. Bubba's truck is a great representation of that. When that truck made its public debut at the 2005 Free 4All it received quite a bit of attention. Bubba and I were both very proud of how that project came out. I wouldn't mind doing a resto on Ted Nugent's 66. I've been a fan for a long time. I always thought it was cool he had a Bronco.

BD: Any closing comments Nick?

N: Guys, it's been great chatting with you. I appreciate all you and your staff are doing with Bronco Driver Mag. It has helped me with my business and has helped the Bronco community as a whole. Its really great that you guys come out to events and rub elbows with the owners of these great old vehicles. Its unbelievable to see how the whole internet/computer thing has brought what was a number of regional enthusiasts into a national group. Its changed how business is done for the vendors and with your magazine out there now, it's really helped unite everyone. The magazine gets better with every issue. Thanks guys.

Nick Menudier of Nick's TriX Early Bronco Restoration & Custom Fabrication

Nick Menudier of Nick's TriX Early Bronco Restoration & Custom Fabrication